Selecting BSL-3 Supply Air Duct Material and Decontamination

March 6, 2024

When considering the material for BSL-3 supply air ducts, the primary objective of biosafety design is to ensure a continuous duct path from the room’s supply diffusers and exhaust outlets (including biological safety cabinets [BSCs]) to ideally an airtight valve in the supply and exhaust ductwork, respectively. This sealed duct section not only maintains the concentration of decontamination gas or vapor required for efficacy but also prevents any leakage of the decontamination agent into surrounding rooms. We advocate for two options while advising against two other alternatives. Selection should be based upon a risk assessment of your facility’s ductwork design.

Option 1: Welded Stainless Steel Ductwork

In the context of BSL-3 facilities, employing welded stainless steel ductwork for both exhaust and supply systems is recommended. This ductwork extends from the BSL-3 laboratory to the airtight isolation damper of the HEPA caisson inlet and the low leakage shut-off control air valve or isolation valve. These supply and exhaust ductwork sections are referred to as “decon duct sections” to distinguish them from ductwork sections where the decon agent is not held for decontamination efficacy. During the decontamination process, the closure of only these two airtight valves is necessary, aligning with current design practices. This approach provides the necessary airtight duct sections for the supply and exhaust decon duct sections.

In terms of operational ease, the preparation for decontamination is streamlined through a dedicated button on the Building Automation System (BAS) interface. However, even with the implementation of welded stainless steel ductwork, it remains imperative to conduct integrity testing of the duct decon sections during the commissioning phase. This precaution is essential as the risk of potential welding pin holes in the ductwork hinges upon the proficiency of the welder involved.

Option 2: Galvanized Ductwork With Sealed Joints

An alternative to Option 1 is round galvanized steel ductwork with press fit joints, where all duct joints are sealed with duct mastic to ensure airtightness. Rectangular or square ductwork can be flanged with neoprene gaskets. Like Option 1, readiness for decontamination requires closing the two airtight valves. It’s advisable to conduct an integrity testing during commissioning. Additionally, this design entails an annual visual examination of duct connections to detect any breaks or deterioration in the mastic at ductwork joints. The risk of ductwork mastic failure hinges on the meticulousness of the mastic application process.

Option 3: Supply Spiral Galvanized and Welded Stainless Steel Flexible Ductwork (Not Recommended)

We discourage the use of galvanized and welded seam stainless steel spiral flexible ductwork for the decontamination section. Welding may not be feasible due to the gauge of the metal.

Option 4: Non-Metal Flexible (Not Recommended)

This approach is discouraged. While some engineers have devised their own modifications, replicating the custom duct seal raises concerns particularly when dealing with a carcinogenic decontamination agent.

Some material options offer unique benefits and considerations, ensuring the effectiveness and safety of BSL-3 laboratory decontamination operations. Option 3 and Option 4 should be avoided.

Contact World BioHazTec to schedule a free 30-minute consultation or send us an email. You are a conversation away from starting down a successful pathway to meet BSL-3 facility compliance.

Share

Featured Posts

How a Simple Click Turned Into Maryland’s First “Biosafety Day”

By Kerstin Haskell, President, World BioHazTec and 2024–2025 President, Chesapeake Area Biological Safety Association (ChABSA) Back in January, I was on the State of Maryland’s website—why, I honestly can’t remember—but there on the homepage I saw a link: “Request a Proclamation.” Something about that link sparked a thought: What if ChABSA's annual symposium had an official proclamation to recognize biosafety and the professionals who safeguard our labs and communities every day? As the President of World BioHazTec and the 2024–2025 President of ChABSA (Chesapeake Area Biological Safety Association), I’m constantly thinking about how we can raise awareness and elevate the biosafety profession—not just within our community, but in the broader public sphere. This felt like a unique opportunity to do just that. So I clicked. What followed was a journey that reminded me of the power of persistence, collaboration, and simply asking. After clicking through, I realized I had to write the proclamation myself. I turned to artificial intelligence, which helped me shape the language, structure, and tone—guiding me through examples and best practices for proclamation writing. With that support, I drafted the text and submitted it through the official portal. Then I waited. A week went by. Silence. I started wondering if it had gone into a bureaucratic black hole. That’s when I remembered my colleague and friend, Brian Castleberry at the Maryland Department of Commerce. I had met Brian through World BioHazTec’s participation in the 2023 Arab Health Show, which was supported by a Maryland export promotion grant for small businesses. I reached out, shared the proclamation request, and Brian kindly forwarded it to a deputy director at the Governor’s Office. Another month passed. Still nothing. Brian followed up again on my behalf (thank you, Brian!), and I continued to wait. Then came a stroke of serendipity. I was in Annapolis testifying before the Maryland House Ways and Means Committee on a proposed tax on life sciences services. Sitting beside me on the panel was Kelly Schulz, President of the Maryland Tech Council. I had long admired Kelly’s work supporting the state’s life sciences community, and this was my chance to finally meet her. After the hearing, we exchanged contact information and started texting. I told her about the proclamation and asked if she might be willing to help. Without hesitation, she said yes. Kelly advised me to follow up after the state’s budget cycle closed at the end of March. I did—and when we met in person, she followed up with the Governor’s Office...right there in front of me. Around the same time, Tracey Brown, World BioHazTec’s Training Manager, who also serves as ChABSA’s Treasurer, reached out to our long-standing partners at the Universities at Shady Grove (USG). ChABSA has proudly supported USG’s Biosafety and Biosecurity Scholarship Program, and the relationship has grown through collaborative events and shared goals. In response to the outreach, Tom Clifford and Joyce Fuhrmann submitted a formal letter of support to the Governor’s Office, strongly advocating for the proclamation to recognize Biosafety Day. Then, just a week before the symposium, I received the news: Governor Wes Moore had officially proclaimed June 4, 2025, as “Biosafety Day” in Maryland. This would not have happened without the advocacy and belief of people like Brian, Kelly, Tom, Joyce, Tracey and others who understand the value of biosafety to Maryland’s workforce, research institutions, and public health system. It’s a reminder that biosafety professionals are making a difference every day—and that our work deserves to be seen and celebrated. Sometimes, all it takes is a click. And a follow-up. And a little courage to ask. Proclamation: Biosafety Day June 4, 2025 WHEREAS, The field of biosafety plays a critical role in protecting public health, scientific research, and the environment by ensuring the safe handling and containment of biological materials in laboratories and research settings; and WHEREAS, Biosafety professionals work diligently to establish and maintain policies, procedures and physical containment measures that prevent accidental exposure to harmful biological agents and promote the responsible use of biotechnology; WHEREAS, Maryland is home to one the nation’s strongest life sciences industries, employing more than 54,000 people across a wide range of roles in research and development, manufacturing, and laboratory operations; and WHEREAS, The Chesapeake Area Biological Safety Association will hold its 35th Scientific Symposium at the Universities at Shady Grove in Rockville, Maryland; and WHEREAS, Through ongoing training, inspections, risk assessments and containment measures, biosafety professionals uphold rigorous standards that protect against biological risks and support safe scientific progress; WHEREAS, The establishment of Biosafety Day serves as an opportunity to highlight the achievements of biosafety professionals, encourages collaboration across disciplines and raise awareness about the importance of effective biosafety programs and protocols. Now therefore, I, Wes Moore, Governor of the State of Maryland, do hereby proclaim June 4, 2025 as Biosafety Day in Maryland, and do commend this observation to all of our citizens.

Read More

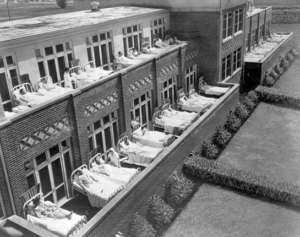

TB and America’s First Public Health Campaign: A Look Back at Early Efforts to Combat Tuberculosis

Early History of Tuberculosis in the U.S. Tuberculosis (TB) has a long, devastating history in the United States. Once known as “The Captain of Death” and the “White Plague,” this deadly disease shaped not only the public’s health but also everyday behaviors and how we as a society responded to infectious threats. Though its grip on the nation has loosened with modern medicine, TB’s early impact on the U.S. led to the creation of some of our first organized public health campaigns. A Devastating Disease: TB’s Early Years in America In the 1700s, tuberculosis earned ominous nicknames like “The Robber of Youth” and “The Captain of Death.” In the 1800s, it became known as the “White Plague,” referencing the pale appearance of its sufferers. It was also commonly called “Consumption” because of its high mortality rate and how victims were consumed by hacking, bloody coughs, debilitating pain in their lungs, and fever, making it impossible to get out of bed. The disease, caused by the bacterium Mycobacterium tuberculosis, spread primarily through the air when an infected person coughed or sneezed. The disease became rampant, thriving in overcrowded urban areas where poor sanitation and malnutrition were common. Without effective treatments, TB was often fatal, leading to widespread fear and stigma. (Stolley & Spector, 1966). 80% of those individuals who developed active tuberculosis died of it. At the time, there was little understanding of how the disease was transmitted, and medical knowledge regarding its treatment was limited. Public health infrastructure was still in its infancy, and many people with TB were left untreated, which further contributed to the spread of the disease. A Public Health Crisis At the beginning of the 19th century, tuberculosis had killed one in seven of all people that had ever lived. During the nineteenth and early twentieth centuries, it was the leading cause of death in the United States, and one of the most feared diseases in the world. It was estimated that, at the turn of the century, 450 Americans died of tuberculosis every day, mostly between the ages of 15 and 44. The death rate in 1900 measured 194 per 100,000 persons. Comparatively, the death rate in America during the COVID-19 pandemic was 61.3 per 100,00 persons. At the turn of the century, TB was a ubiquitous component of American society and culture. While it was a disease that typically impacted lower socio-economic classes who often resided in overcrowded cities, living and working in poorly ventilated structures, more prominent Americans were not beyond TB’s reach. Among the list of well-known Americans who succumbed to TB included former Presidents James Monroe and Andrew Jackson, two of Abraham Lincoln’s sons, two of Richard Nixon’s brothers, First Lady Eleanor Roosevelt, authors Henry David Thoreau, Edward Bellamy, George Orwell, Stephen Crane, and Thomas Wolfe, actor W.C. Fields, business tycoon Jay Gould, musicians Chick Webb and Jimmy Blanton, and Clara Barton, founder of the American Red Cross, just to name a few. Early Infectious Disease Control: America’s First Public Health Campaign The Sanatorium Movement By the late 1800s, public health leaders in the U.S. recognized the need to address TB through organized medical and social interventions. One of the earliest responses to TB was the establishment of sanatoriums, specialized treatment centers designed to isolate and care for people with tuberculosis. The idea behind sanatoriums was simple: fresh air, rest, and good nutrition were believed to help patients recover. By the late 1800s and early 1900s, doctors and health officials discovered that TB was most contagious during the active stages of the disease. Isolating patients in sanatoriums reduced the risk of spreading TB to the general population. These institutions were typically located in rural areas or places with clean air, and patients were encouraged to spend most of their time outdoors. These facilities not only provided physical care but also helped reduce the stigma surrounding TB, as they became recognized as centers for both healing and hope. Many sanatoriums were funded by a combination of public funds, charitable donations, and private contributions, reflecting the community-wide effort to address the epidemic. Image from the University of Virginia's Claude Moore Health Sciences Library as appeared in the digital exhibit, "The American Lung Association Crusade" at http://exhibits.hsl.virginia.edu/alav/tu Life in the Sanitorium In the first decades of the 20th century, one out of every 170 Americans lived in a sanatorium, some for many years. For many, these institutions were their last hope. While sanatoriums were not a cure for TB, they provided some relief, particularly for patients in the early stages of the disease. However, life in the Sanitoriums was not easy. Patients often left for sanatoriums in the middle of the night, without telling people. They quit their jobs, or they just left to protect their families. Entering a sanatorium required complete submission. Physicians and nurses regulated every moment of the day. When people first came to a sanatorium, many were put on 24-hour rest. All their meals were brought to bed on trays. They were required to use bedpans. Many facilities were segregated by race, and some African Americans, barred from whites-only sanatoriums, helped start their own. Despite the hardships, sanatoriums offered a sense of community for those afflicted by the disease. They were isolated from the fear of infecting others and often found solace in the companionship of fellow patients. For all the freedoms they lost, patients were able to embrace the idea of healing and hope in a place that was devoted to their care. The success of these early sanatoriums served to influence later public health policy in the U.S. The idea of isolating infected individuals, as seen in the sanatoriums, laid the groundwork for quarantine practices, which were later used for controlling other infectious diseases, including influenza, smallpox, and even COVID-19. TB Public Health Campaign: The Foundation for Modern Infectious Disease Control By the early 20th century, public health officials realized that isolating TB patients was just one part of the solution. The other part was educating the public about TB transmission and prevention. The establishment of the National Tuberculosis Association in 1904 (now the American Lung Association) marked an important milestone in raising awareness about TB. The association’s work centered around educating the public on the importance of early detection, promoting hygiene practices like covering one’s mouth when coughing, and encouraging people to seek medical treatment as soon as symptoms appeared. Public health campaigns also emphasized the importance of improving living conditions. Poor nutrition, overcrowded housing, and lack of access to healthcare were known to exacerbate TB, and improving these factors became a key focus for public health advocates. As TB research progressed and medical treatments were developed, quarantine and isolation protocols continued to be important public health tools. The early emphasis on isolating individuals with active TB in sanatoriums eventually led to more formal quarantine measures for individuals diagnosed with the disease. This practice of isolation not only reduced the risk of transmission but also contributed to the eventual creation of specialized infectious disease units in hospitals. Conclusion Early public health responses to tuberculosis in the United States laid the foundation for modern practices in infectious disease prevention and management. The establishment of sanatoriums, public health campaigns to educate the public, and advances in medical research helped reduce TB-related mortality. Additionally, the development of isolation protocols and laboratory biosafety measures, informed by TB research, established the groundwork for how the U.S. manages infectious diseases today. Though TB is no longer the threat it once was, the lessons learned during this time continue to influence how we approach modern public health crises. References Ahmad FB, Cisewski JA, Xu J, Anderson RN. (2022). COVID-19 Mortality Update — United States, Retrieved from https://www.cdc.gov/mmwr/volumes/72/wr/mm7218a4.htm American Experience. (2015). The Forgotten Plague. Retrieved from https://www.pbs.org/wgbh/americanexperience/films/plague/#transcript American Lung Association. (2020). A Brief History of Tuberculosis in the United States. Retrieved from https://www.lung.org/research/trends-in-lung-disease/tuberculosis Centers for Disease Control and Prevention (CDC). (2021). Tuberculosis (TB) History and Timeline. Retrieved from https://www.cdc.gov/tb/about/history/default.htm Fennell, M. L. (2018). The Rise and Fall of the Tuberculosis Sanatorium: The Role of Sanatoriums in Early Public Health Responses. Journal of the History of Medicine, 73(2), 130-142. Mackenzie, R. W. (2002). Public Health and Tuberculosis Control in the United States. Health Affairs, 21(3), 182-192. Rosen, G. (1993). A History of Public Health. Johns Hopkins University Press. Rothman, Sheila M. Living in the Shadow of Death: Tuberculosis and the Social Experience of Illness in American History (New York: BasicBooks, 1994) Snider, G.L. (1997). Tuberculosis then and now: a personal perspective on the last 50 years. Retrieved from https://pubmed.ncbi.nlm.nih.gov/9027277/ Stolley, P. D., & Spector, W. S. (1966). Tuberculosis in the United States: The Role of Medical Interventions and Public Health Efforts in Reducing Tuberculosis Mortality. The Journal of Infectious Diseases, 118(3), 184-197.

Read More

“Like Patenting the Sun”: America’s Fight Against Polio and the Power of a Vaccine

In the early 1950s, as the United States relaxed in the post-WWII glow, a terrifying disease threatened to disrupt the safety and peace that families had fought so hard to secure. Polio, a virus that cast a shadow over families for decades, surged to alarming levels, with a peak of 57,879 reported cases in 1952, resulting in 3,145 deaths. This terrifying epidemic, which primarily struck children, shattered the idealized vision of suburban life and posed an existential threat to the very idea of family safety in a modern, scientifically advanced world. A Nation Gripped by Fear For middle-class American families, polio was an unwelcome intrusion into a life they believed they could control. The postwar years had promised safety—victory over the Great Depression, success in World War II, and the newfound comforts of suburban living. But polio, which could paralyze or kill seemingly without reason, introduced a sense of vulnerability and helplessness. The random nature of its spread left families in constant fear. An otherwise healthy child could be struck down in an instant, leaving parents to wonder where they went wrong. The polio virus could take anywhere from six to twenty days to incubate and remained contagious for up to two weeks. Its long incubation period, coupled with the fact that the virus was highly stable in the environment, made it nearly impossible for experts to track how it was spreading. Some believed it was spread through water, leading to public pools and beaches being closed during the summer months. In fact, one book about the epidemic is aptly titled The Summer Plague, emphasizing how the virus seemed to return each year, adding to the dread. The Impact of Polio on Daily Life During the height of the epidemic, life as usual was put on pause. Swimming pools, movie theaters, and even playgrounds were shut down to protect children from the virus. Parents, gripped by the fear that their children could "catch polio" at any given moment, kept them isolated, away from friends, and away from public spaces. Rumors abounded, blaming soft drinks, weather patterns, or even the use of paper money for spreading the disease. Health officials, overwhelmed by the unpredictability of the virus, took extreme measures—such as isolating children suspected of being infected and quarantining them in sanitariums. By the time the polio epidemic reached its peak, fear was ingrained into American life. Each summer, when the virus was most active, the country seemed to hold its breath, waiting for the next wave of infections. Counterintuitive Culprit: Hygiene and Clean Water Polio had existed in obscure forms before the twentieth century, with occasional outbreaks in the 18th and 19th centuries. But it wasn't until the early 1900s that the disease became a widespread epidemic. The clue to its terrifying rise was hidden in something presumably beneficial: improving sanitation and clean water systems. Before the 20th century, the virus was rampant in water supplies. When a very young child was exposed, it would often cause a mild reaction, such as diarrhea, that would lead to lifelong immunity. But as public health efforts improved sanitation and water systems, children no longer had the mild exposure that would naturally build immunity. As a result, polio began to affect older children and young adults who were not immune. With no understanding of the virus’s transmission or how to prevent it, epidemics like the one in 1916, and later ones in the 1940s and 1950s, were disastrous. Polio's victims were disproportionately from the middle class, which struck fear into this emblem of American global superiority. The virus struck at a time when modern society had assumed it had mastered infectious diseases. Polio was the cruel reminder that not even the most advanced systems could protect against everything. The Search for a Vaccine: A Triumph of Science and Collaboration In the midst of this public health crisis, hope emerged in the form of a vaccine. Dr. Jonas Salk, a name now synonymous with polio eradication, developed the inactivated polio vaccine (IPV), which would change the course of history. By 1955, the vaccine had been tested and found to be both safe and effective. This was a monumental breakthrough. For Salk, the success of the vaccine was not about personal profit—he famously refused to patent it, saying it would be like “patenting the sun.” The introduction of the vaccine led to a massive public health campaign. Between 1955 and 1962, over 400 million doses of the vaccine were distributed, dramatically reducing cases by 90%. Polio, once the most feared disease in America, began to fade into memory. The collective effort that brought the vaccine to fruition—through the leadership of President Franklin Roosevelt, the work of scientists like Salk, and the bravery of volunteers who tested the vaccine—was a triumph of cooperation and public trust in science. The Cold War Twist: The Sabin Vaccine and Global Cooperation While Salk’s vaccine was taking hold in the U.S., another breakthrough emerged. Dr. Albert Sabin developed an oral polio vaccine, which could be taken in a simple pill rather than requiring an injection. However, by the time Sabin was ready to test his live-virus vaccine in the U.S., many children had already received the Salk vaccine, so he turned to Eastern Europe for testing. In one of the most remarkable stories of Cold War collaboration, Sabin tested his vaccine on millions of children in the Soviet Union, Hungary, and other Eastern European countries, where the results were overwhelmingly positive. The success of the Sabin vaccine in these countries demonstrated the power of international cooperation during a time of immense political tension. Hungary, in particular, became a pioneer in polio vaccination, beginning its nationwide vaccination campaign in 1959—four years before the United States adopted the Sabin vaccine. This global effort to eradicate polio marked a rare moment of unity in an era defined by the ideological divide of the Cold War. A Faint Memory: Polio's Legacy and the Ongoing Struggle By the end of the 20th century, the specter of polio had receded into the background of public consciousness. With vaccination programs and public health campaigns, polio became a disease of the past in many parts of the world. However, the legacy of this disease lives on, not only in the memories of those who lived through the epidemic, but also in the ongoing fight to eradicate it completely. In some ways, polio is now a victim of its own success. Today’s parents, who have never seen the disease’s devastating effects, may take vaccines for granted. But the history of polio serves as a reminder of the power of science, collaboration, and public trust. It also underscores the importance of remaining vigilant in the face of new and evolving health threats. References Janssen, Volker. (2023). When Polio Triggered Fear and Panic Among Parents in the 1950s. Retrieved from https://www.history.com/news/polio-fear-post-wwii-era Kurlander, Carl. (2020). How the deadly polio epidemic changed American life for decades before a vaccine was found. Retrieved from https://www.milwaukeeindependent.com/syndicated/deadly-polio-epidemic-changed-american-life-decades-vaccine-found/ Lienhard, John H. Polio and Clean Water. Retrieved from https://engines.egr.uh.edu/episode/1527 Rochford, Rosemary. (2022). A virologist explains polio’s history as fears of a resurgence grow. Retrieved from https://arkansasadvocate.com/2022/09/08/a-virologist-explains-polios-history-as-fears-of-a-resurgence-grow/ Vargha, Dóra. (2018). Polio Across the Iron Curtain: Hungary’s Cold War with an Epidemic. Retrieved from https://www.ncbi.nlm.nih.gov/books/NBK565345/ Weeks, Linton. (2015). Defeating Polio, The Disease That Paralyzed America. Retrieved from https://www.npr.org/sections/npr-history-dept/2015/04/10/398515228/defeating-the-disease-that-paralyzed-america

Read More