Early History of Tuberculosis in the U.S.

Tuberculosis (TB) has a long, devastating history in the United States. Once known as “The Captain of Death” and the “White Plague,” this deadly disease shaped not only the public’s health but also everyday behaviors and how we as a society responded to infectious threats. Though its grip on the nation has loosened with modern medicine, TB’s early impact on the U.S. led to the creation of some of our first organized public health campaigns.

A Devastating Disease: TB’s Early Years in America

In the 1700s, tuberculosis earned ominous nicknames like “The Robber of Youth” and “The Captain of Death.” In the 1800s, it became known as the “White Plague,” referencing the pale appearance of its sufferers. It was also commonly called “Consumption” because of its high mortality rate and how victims were consumed by hacking, bloody coughs, debilitating pain in their lungs, and fever, making it impossible to get out of bed.

The disease, caused by the bacterium Mycobacterium tuberculosis, spread primarily through the air when an infected person coughed or sneezed. The disease became rampant, thriving in overcrowded urban areas where poor sanitation and malnutrition were common. Without effective treatments, TB was often fatal, leading to widespread fear and stigma. (Stolley & Spector, 1966). 80% of those individuals who developed active tuberculosis died of it.

At the time, there was little understanding of how the disease was transmitted, and medical knowledge regarding its treatment was limited. Public health infrastructure was still in its infancy, and many people with TB were left untreated, which further contributed to the spread of the disease.

A Public Health Crisis

At the beginning of the 19th century, tuberculosis had killed one in seven of all people that had ever lived. During the nineteenth and early twentieth centuries, it was the leading cause of death in the United States, and one of the most feared diseases in the world.

It was estimated that, at the turn of the century, 450 Americans died of tuberculosis every day, mostly between the ages of 15 and 44. The death rate in 1900 measured 194 per 100,000 persons. Comparatively, the death rate in America during the COVID-19 pandemic was 61.3 per 100,00 persons.

At the turn of the century, TB was a ubiquitous component of American society and culture. While it was a disease that typically impacted lower socio-economic classes who often resided in overcrowded cities, living and working in poorly ventilated structures, more prominent Americans were not beyond TB’s reach. Among the list of well-known Americans who succumbed to TB included former Presidents James Monroe and Andrew Jackson, two of Abraham Lincoln’s sons, two of Richard Nixon’s brothers, First Lady Eleanor Roosevelt, authors Henry David Thoreau, Edward Bellamy, George Orwell, Stephen Crane, and Thomas Wolfe, actor W.C. Fields, business tycoon Jay Gould, musicians Chick Webb and Jimmy Blanton, and Clara Barton, founder of the American Red Cross, just to name a few.

Early Infectious Disease Control: America’s First Public Health Campaign

The Sanatorium Movement

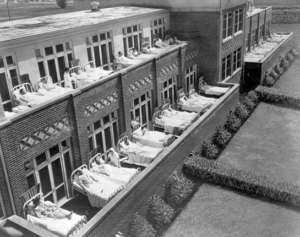

By the late 1800s, public health leaders in the U.S. recognized the need to address TB through organized medical and social interventions. One of the earliest responses to TB was the establishment of sanatoriums, specialized treatment centers designed to isolate and care for people with tuberculosis. The idea behind sanatoriums was simple: fresh air, rest, and good nutrition were believed to help patients recover.

By the late 1800s and early 1900s, doctors and health officials discovered that TB was most contagious during the active stages of the disease. Isolating patients in sanatoriums reduced the risk of spreading TB to the general population. These institutions were typically located in rural areas or places with clean air, and patients were encouraged to spend most of their time outdoors. These facilities not only provided physical care but also helped reduce the stigma surrounding TB, as they became recognized as centers for both healing and hope. Many sanatoriums were funded by a combination of public funds, charitable donations, and private contributions, reflecting the community-wide effort to address the epidemic.

Image from the University of Virginia's Claude Moore Health Sciences Library as appeared in the digital exhibit, "The American Lung Association Crusade" at http://exhibits.hsl.virginia.edu/alav/tu

Life in the Sanitorium

In the first decades of the 20th century, one out of every 170 Americans lived in a sanatorium, some for many years. For many, these institutions were their last hope. While sanatoriums were not a cure for TB, they provided some relief, particularly for patients in the early stages of the disease. However, life in the Sanitoriums was not easy.

Patients often left for sanatoriums in the middle of the night, without telling people. They quit their jobs, or they just left to protect their families. Entering a sanatorium required complete submission. Physicians and nurses regulated every moment of the day. When people first came to a sanatorium, many were put on 24-hour rest. All their meals were brought to bed on trays. They were required to use bedpans. Many facilities were segregated by race, and some African Americans, barred from whites-only sanatoriums, helped start their own.

Despite the hardships, sanatoriums offered a sense of community for those afflicted by the disease. They were isolated from the fear of infecting others and often found solace in the companionship of fellow patients. For all the freedoms they lost, patients were able to embrace the idea of healing and hope in a place that was devoted to their care. The success of these early sanatoriums served to influence later public health policy in the U.S. The idea of isolating infected individuals, as seen in the sanatoriums, laid the groundwork for quarantine practices, which were later used for controlling other infectious diseases, including influenza, smallpox, and even COVID-19.

TB Public Health Campaign: The Foundation for Modern Infectious Disease Control

By the early 20th century, public health officials realized that isolating TB patients was just one part of the solution. The other part was educating the public about TB transmission and prevention. The establishment of the National Tuberculosis Association in 1904 (now the American Lung Association) marked an important milestone in raising awareness about TB. The association’s work centered around educating the public on the importance of early detection, promoting hygiene practices like covering one’s mouth when coughing, and encouraging people to seek medical treatment as soon as symptoms appeared. Public health campaigns also emphasized the importance of improving living conditions. Poor nutrition, overcrowded housing, and lack of access to healthcare were known to exacerbate TB, and improving these factors became a key focus for public health advocates.

As TB research progressed and medical treatments were developed, quarantine and isolation protocols continued to be important public health tools. The early emphasis on isolating individuals with active TB in sanatoriums eventually led to more formal quarantine measures for individuals diagnosed with the disease. This practice of isolation not only reduced the risk of transmission but also contributed to the eventual creation of specialized infectious disease units in hospitals.

Conclusion

Early public health responses to tuberculosis in the United States laid the foundation for modern practices in infectious disease prevention and management. The establishment of sanatoriums, public health campaigns to educate the public, and advances in medical research helped reduce TB-related mortality. Additionally, the development of isolation protocols and laboratory biosafety measures, informed by TB research, established the groundwork for how the U.S. manages infectious diseases today. Though TB is no longer the threat it once was, the lessons learned during this time continue to influence how we approach modern public health crises.

References

Ahmad FB, Cisewski JA, Xu J, Anderson RN. (2022). COVID-19 Mortality Update — United States, Retrieved from https://www.cdc.gov/mmwr/volumes/72/wr/mm7218a4.htm

American Experience. (2015). The Forgotten Plague. Retrieved from https://www.pbs.org/wgbh/americanexperience/films/plague/#transcript

American Lung Association. (2020). A Brief History of Tuberculosis in the United States. Retrieved from https://www.lung.org/research/trends-in-lung-disease/tuberculosis

Centers for Disease Control and Prevention (CDC). (2021). Tuberculosis (TB) History and Timeline. Retrieved from https://www.cdc.gov/tb/about/history/default.htm

Fennell, M. L. (2018). The Rise and Fall of the Tuberculosis Sanatorium: The Role of Sanatoriums in Early Public Health Responses. Journal of the History of Medicine, 73(2), 130-142.

Mackenzie, R. W. (2002). Public Health and Tuberculosis Control in the United States. Health Affairs, 21(3), 182-192.

Rosen, G. (1993). A History of Public Health. Johns Hopkins University Press.

Rothman, Sheila M. Living in the Shadow of Death: Tuberculosis and the Social Experience of Illness in American History (New York: BasicBooks, 1994)

Snider, G.L. (1997). Tuberculosis then and now: a personal perspective on the last 50 years. Retrieved from https://pubmed.ncbi.nlm.nih.gov/9027277/

Stolley, P. D., & Spector, W. S. (1966). Tuberculosis in the United States: The Role of Medical Interventions and Public Health Efforts in Reducing Tuberculosis Mortality. The Journal of Infectious Diseases, 118(3), 184-197.

Read More